- Home

- MediaOutReach

- Southco's Blind Mate Floating Mechanism Empowers Efficient Cooling in Data Centers

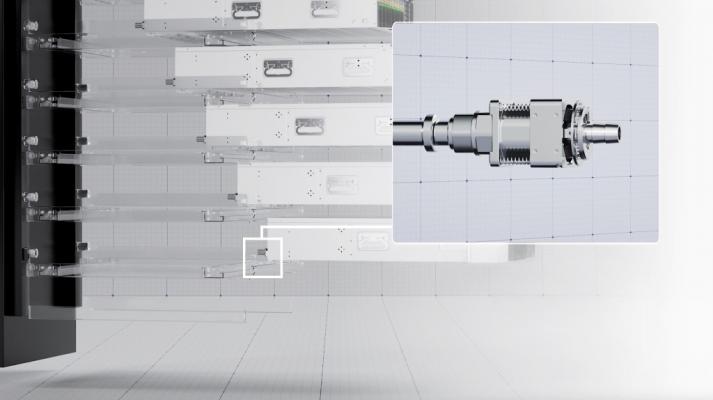

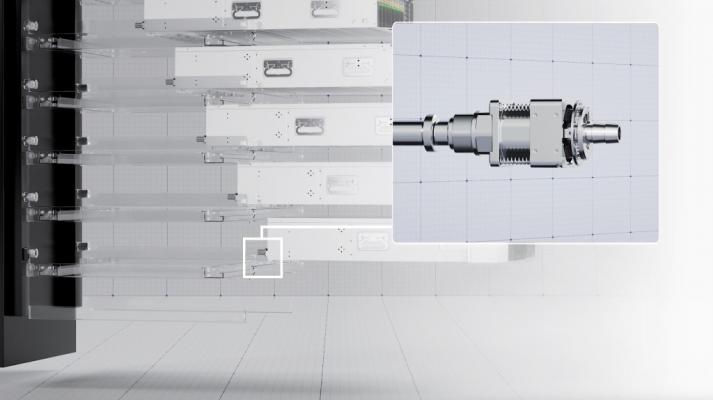

Southco's Blind Mate Floating Mechanism Empowers Efficient Cooling in Data Centers

Selasa, 20 Januari 2026 | 09:25

HONG KONG SAR -

Media OutReach Newswire

- 20 January 2026 - Global computing power is growing aggressively and

pushing high-density chip power consumption. As this power density

increases, traditional air cooling is reaching its physical limits, and

once-fringe liquid cooling technology, boasting thermal efficiency

hundreds of times greater than air cooling, is rapidly becoming core

infrastructure.

Driven by global sustainability targets and the need for high-performance, energy-efficient infrastructures, new large data centers must achieve their targeted PUE values, accelerating the industry towards large-scale liquid cooling. However, reliability issues stemming from insufficient mechanical tolerances at the connection points of liquid cooling systems are becoming a critical bottleneck for energy efficiency upgrades and stable operation. Southco recognizes the severity of this challenge and is committed to providing breakthrough solutions.

Minor Deviations, Major Costs

During the large-scale deployment of liquid cooling technology, the

reliability of connection interfaces is vital. According to key data

from the Open Compute Project (OCP) "Rack-Mounted Manifold Requirements

and Verification Guidelines," a mere 1mm increase in mechanical

deviation at liquid cooling interfaces can significantly raise system

flow resistance by 15%, leading to a 7% increase in pump energy

consumption! This is no trivial amount; in a hyperscale data center with

thousands of interfaces, it translates to millions of kilowatt-hours of

additional energy consumption and substantial operational costs each

year. More concerning is that traditional rigid connection solutions

typically offer only ±0.5mm of static tolerance, which proves inadequate

in complex real-world environments like these:

- - Accumulation of Multi-Dimensional Installation Deviations: In mixed deployment scenarios of widely used EIA-310-D standard racks and advanced ORV3 open architectures, rack installation tolerances can accumulate up to ±3.2mm, far exceeding the limits of traditional solutions.

- - Dynamic Vibration Impacts: In ISTA 3-E vibration tests simulating real transportation and operating environments, interface displacement often exceeds 2.8mm, posing significant risks of leaks or connection failures.

- - Material Thermal Expansion Effects: Under a typical temperature change of 55°C, copper alloy manifolds can expand approximately 1.2mm per meter, continuously challenging fixed interfaces.

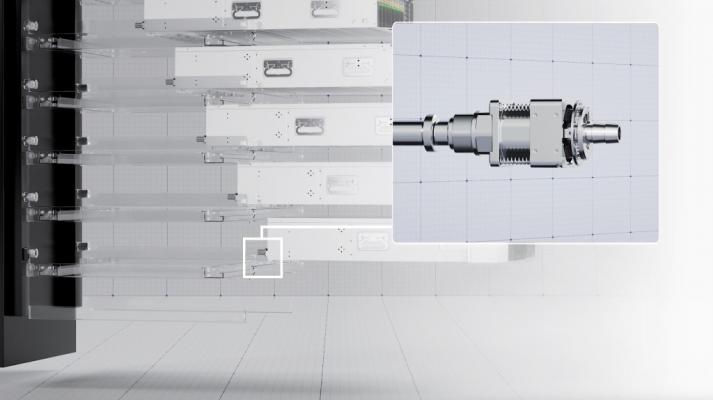

Blind Mate Quick Disconnect: A Connection for a Dynamic World

As a century-old expert in precision engineering, Southco confronts this challenge head-on with the launch of the revolutionary new "Blind Mate Floating Mechanism" liquid cooling connection solution. This innovation is not just a new product; it is a systematic response to profound insight into industry pain points.

Current Status and Trends of Blind Mate Floating Technology

Liquid cooling technology is rapidly gaining traction in high-performance computing (HPC), AI training clusters, and hyperscale data centers. Blind mate technology allows devices to connect without precise visual alignment, making it a core interface solution for rapid deployment and efficient maintenance in liquid cooling systems (especially cold plate systems). The development trends are clear:

- - Higher Tolerance Capacity: Adapting to more complex rack environments and dynamic changes is essential.

- - Increased Reliability: Zero leakage, long lifespan, and resistance to extreme conditions are basic requirements.

- - Intelligent Integration: Integrating sensors for flow, temperature, pressure, etc., for real-time monitoring and predictive maintenance is a future direction.

- - Standardization and Compatibility: Supporting OCP ORV3 and other open standards for seamless integration across platforms and manufacturers.

- - Lightweight and Compact Design: Meeting the demands of higher density deployments.

Advantages Over Traditional Solutions

Compared to traditional fixed or simple floating heat transfer connection solutions, Southco's "Blind Mate Floating Mechanism" offers a qualitative leap with advantages evident across multiple dimensions.

- - Three-Dimensional Dynamic Tolerance Control: Southco's innovative design features a groundbreaking three-dimensional dynamic compensation mechanism: ±4mm of floating tolerance in the radial direction (2° tilt compensation) and 6mm of displacement absorption capacity in the axial direction. This far exceeds common static tolerances in the industry, effectively absorbing and adapting to all previously mentioned installation tolerances, vibration displacements, and thermal expansion deformations.

- - Self-Centering Mechanism: When the liquid-cooled blind-plug connector is unplugged, the floating structure automatically resets to the center position, ensuring sufficient floating space for plugging and unplugging operations, fully meeting the strict tolerance requirements of OCP and ORV3 standards.

- - Outstanding Sealing Performance for Long-Term Operation: Products endure rigorous ASME B31.3 standard 300psig burst pressure tests, ensuring over 10 years of service life, providing long-term stability for data centers, an achievement traditional solutions cannot match.

- - Efficient Maintenance and Significant Cost Reduction: Featuring the Universal Quick Disconnect Blind (UQDB) interface, the design enables genuine "blind operations," allowing server maintenance without precise alignment or specialized tools. Quick disconnect capabilities make server replacement or upgrades as convenient as "hot plugging," reducing downtime and related losses by over 90%.

The Necessity of Blind Mate Floating Mechanism

In AI computing clusters and next-generation data centers, adopting

advanced connection solutions like Southco's "Blind Mate Floating

Mechanism" is no longer optional, but essential.

- - Key to Overcoming Cooling Bottlenecks: High power density is an inevitable trend; traditional cooling and rigid connections can no longer meet the demand. The Blind Mate Floating Mechanism is foundational for unleashing the full potential of liquid cooling and ensuring efficient, stable operation of cooling systems.

- - Cornerstone of Business Continuity: The costs of data center downtime are immense. The rapid, reliable thermal maintenance supported by the Blind Mate Floating Mechanism is vital for ensuring uninterrupted operation of critical business activities 24/7.

- - Core to Achieving Green and Low-Carbon Goals: Minor deviations in connectors leading to increased flow resistance can significantly elevate pump energy consumption. Its high-tolerance, low-flow resistance design directly contributes to lowering data center PUE values, making it an important element in energy conservation and emissions reduction goals.

- - Flexibility for Future Expansion and Upgrading: Modular and standardized design enables data centers to expand capacity and upgrade equipment more flexibly, easily accommodating future increases in computing power demand and technological iterations.

Continuous Innovation, Intelligent Cooling Ahead

According to the "Open Rack V3" white paper, liquid cooling penetration in hyperscale data centers is expected to exceed 40% by 2025. Southco continues to invest in R&D to iterate floating mechanism technology:

* Exploring lightweight high-performance materials (like PPSU thermoplastic) to reduce weight while maintaining strength.

* Advancing intelligent sensor integration for real-time monitoring of key parameters like flow and temperature, providing data for predictive maintenance and energy efficiency optimization.

* Deepening ecosystem collaboration and standardization to promote liquid cooling interfaces in higher density, lower TCO, and broader applications.

As liquid cooling technology transitions from optional to essential, Southco's "Blind Mate " represents a precision engineering product innovation, and a profound understanding of cooling challenges in the data center industry. By integrating over a century of precision mechanical design expertise with innovative three-dimensional dynamic tolerance control technology, Southco strives to help global data centers break through cooling bottlenecks, building a more efficient, reliable, and greener foundation for computing power, empowering infinite possibilities in the digital age.

For more information, please click

here for more details.

Catpion: Southco's Floating Mechanism

BERITA LAINNYA

Selasa, 20 Januari 2026 | 09:32

Selasa, 20 Januari 2026 | 09:30

Selasa, 20 Januari 2026 | 09:29

Selasa, 20 Januari 2026 | 09:25

Selasa, 20 Januari 2026 | 09:23

Selasa, 20 Januari 2026 | 09:21

Selasa, 20 Januari 2026 | 09:20

Senin, 19 Januari 2026 | 21:13

Senin, 19 Januari 2026 | 21:11

Senin, 19 Januari 2026 | 21:09

Senin, 19 Januari 2026 | 15:10